- Joined

- Oct 7, 2011

- Messages

- 62

- Points

- 0

Ok so basically I have 2 questions I want to knock out in 1 thread.

1.) It's obvious that a laser DOT produces heat if powerful enough. So for experimental sake we'll use variable 1 as a >1000mW 445 laser.

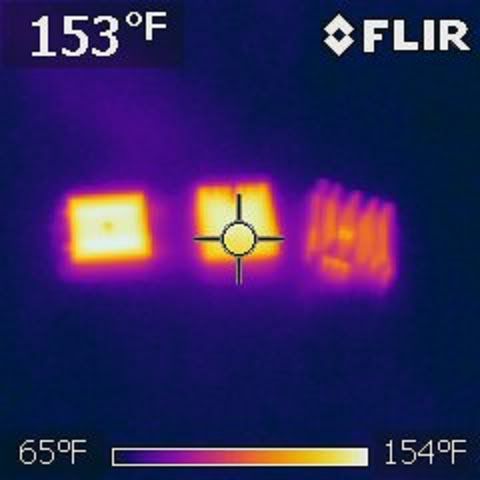

So if you were to capture the laser DOT with a thermal imaging camera it would obviously produce a signature on the camera.

What I am basically asking is does the beam produce heat in the air? Meaning will a thermal imaging camera pick up a heating signature from the beam and not just the dot?

2.) I notice a vast majority of commercial lasers out for sale have there housing units and heat sinks are painted black. My question now is are they painted black just for the looks or does it act as a catalyst to draw heat out of the heat sink to the surface?

Any info is appreciated.

-Cheers

1.) It's obvious that a laser DOT produces heat if powerful enough. So for experimental sake we'll use variable 1 as a >1000mW 445 laser.

So if you were to capture the laser DOT with a thermal imaging camera it would obviously produce a signature on the camera.

What I am basically asking is does the beam produce heat in the air? Meaning will a thermal imaging camera pick up a heating signature from the beam and not just the dot?

2.) I notice a vast majority of commercial lasers out for sale have there housing units and heat sinks are painted black. My question now is are they painted black just for the looks or does it act as a catalyst to draw heat out of the heat sink to the surface?

Any info is appreciated.

-Cheers